- Home

- About Us

- Our Products

- Our Clients

- Blog

- Contact Us

Quick Enquiry

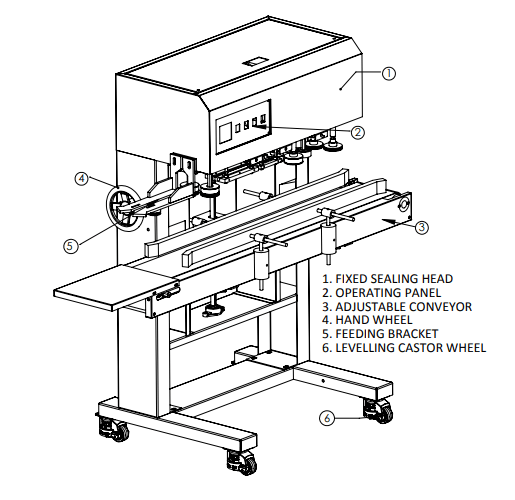

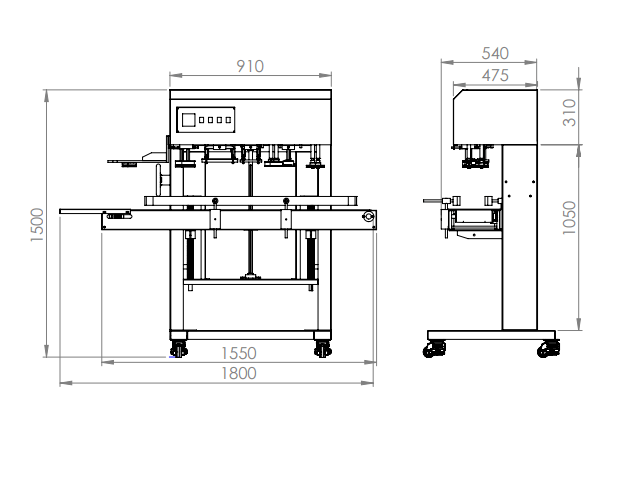

Vertical Band Sealer

IP-VT-1000

The Super sealer vertical/Horizontal continous heat bag sealer continously seals a wide range of bag materials at high speed and efficiency. The heavy duty IP-VT-1000 painted construction in combination with proven band sealing technology and opterator friendly controls ensures continuous duty performnace in demanding applications.

Dry Solid Powder

Dry Solid Powder  Agro Powder

Agro Powder Milk Powder

Milk Powder Snacks

Snacks Pulses/Lentils

Pulses/Lentils Coffee

Coffee  Ground Spices

Ground Spices Seeds

Seeds Poultry

Poultry

| Product | : | IP-VT-1000 |

| Seal length | : | Unlimited |

| Seal width | : | 2 – 25 mm |

| Type of machine | : | Continuous sealer, Semi-automatic |

| Model | : | Floor |

| Covering | : | Mild Steel |

| Conveyor Type | : | Adjustable 100mm to 550mm |

| Type of film | : | LD, PP, HM, Any type of Laminated Pouches, Aluminium foil paper |

| Type of package | : | Bag / Pouch |

| Feeding Direction | : | Left to Right (or) Right to Left |

| Type of product | : | Granulate, Powder, Solid |

| Sealing speed | : | Max. 8 to 12 meters per minute |

| Optional | : | Gas flushing / vacuum / Printing / Trimmer / Sealing Width |

| Voltage | : | 230 V |

- Powder coat paint finish

- Heavy duty band sealing technology

- Variable speed

- PID temperature controls

- Easy lift front cover

- Mobile base and gas strut adjustable pedestal

- Clean and Durable

- Optimum seal quality and performance

- Ease of matching conveyor speeds and flexibility

- Accurate and consistent sealing temperature

- Quick access to all componments

- Simple set up and adjustment

- Oil free low maintanance

Need a high-efficiency sealing solution for standing pouches? Inpak Automation & Packaging Machines presents the Vertical Band Sealer, designed for airtight and durable packaging across multiple industries. Whether you’re sealing food products, pharmaceuticals, or industrial supplies, our Vertical Band Sealers ensure maximum freshness and product integrity.

Why Choose Inpak’s Vertical Band Sealer?

- Superior Sealing Performance

- High-speed continuous sealing for increased productivity.

- Adjustable sealing height to accommodate different pouch sizes.

- Temperature Precision: Consistent heat control for airtight, tamper-proof packaging.

Advanced Technical Features

- Sealing Speed: Up to 15 meters per minute for fast and efficient sealing.

- Temperature Control: Adjustable 0-300°C settings for various pouch materials.

- Robust Build: Constructed with food-grade stainless steel (SS-304) for hygiene and longevity.

- Versatile Film Compatibility: Works with polyethylene (PE), polypropylene (PP), laminated films, and biodegradable pouches.

- User-Friendly Digital Panel: Touchscreen interface for easy temperature and speed adjustments.

Unique Selling Points

- Compact & Space-Saving Design: Perfect for small and large-scale packaging lines.

- Energy-Efficient & Low Maintenance: Designed for durability and cost-effective operation.

- Customised Configurations: Adjustable conveyor speed and height for various product sizes.

- Industry-Approved Compliance: Certified for FDA, GMP, and CE standards.

Industries We Serve

- Food & Beverages: Sealing flour, rice, sugar, dry fruits, snacks, and dairy products.

- Pharmaceuticals: Packaging medicine sachets, bandages, and surgical supplies.

- Cosmetics & Personal Care: Sealing pouches for creams, powders, and toiletries.

- Industrial & Chemical Applications: Secure packaging for fertilisers, detergents, and hardware components.

Enhance Your Packaging with Inpak’s Vertical Band Sealer

Achieve consistent, reliable, and airtight sealing with Inpak’s Vertical Band Sealer. Designed for efficiency and durability, it is the ultimate choice for modern packaging lines.

FAQs for Inpak’s Vertical Band Sealer

- What types of pouches work best with this sealer?

Our Vertical Band Sealer is compatible with a variety of pouch materials, including:

- Polyethylene (PE)

- Polypropylene (PP)

- Laminated films

- Biodegradable pouches

It is ideal for sealing stand-up pouches, gusseted bags, and other flexible packaging materials.

- How does this compare to horizontal band sealers?

- Vertical Band Sealer: Best for sealing products in standing pouches, especially liquids, powders, and granular items.

- Horizontal Band Sealer: More suitable for flat pouches and bags that do not require vertical positioning.

If your product contains liquids or powders, a vertical sealer is recommended for leak-proof sealing.

- What maintenance does the machine require?

To ensure optimal performance, regular maintenance includes:

- Cleaning the sealing belts and heating elements after use.

- Checking and replacing worn-out Teflon belts as needed.

- Lubricating moving parts periodically to prevent wear and tear.

- Inspecting temperature settings and calibration for consistent sealing quality.

- Can it seal liquids in standing pouches?

Yes, our Vertical Band Sealer is specifically designed for sealing liquid-filled standing pouches. It ensures leak-proof and airtight packaging, making it ideal for sealing sauces, juices, soups, and other liquid-based products.

Let me know if you need more FAQs or modifications!

Product Gallery