- Home

- About Us

- Our Products

- Our Clients

- Gallery

- Blog

- Contact Us

Quick Enquiry

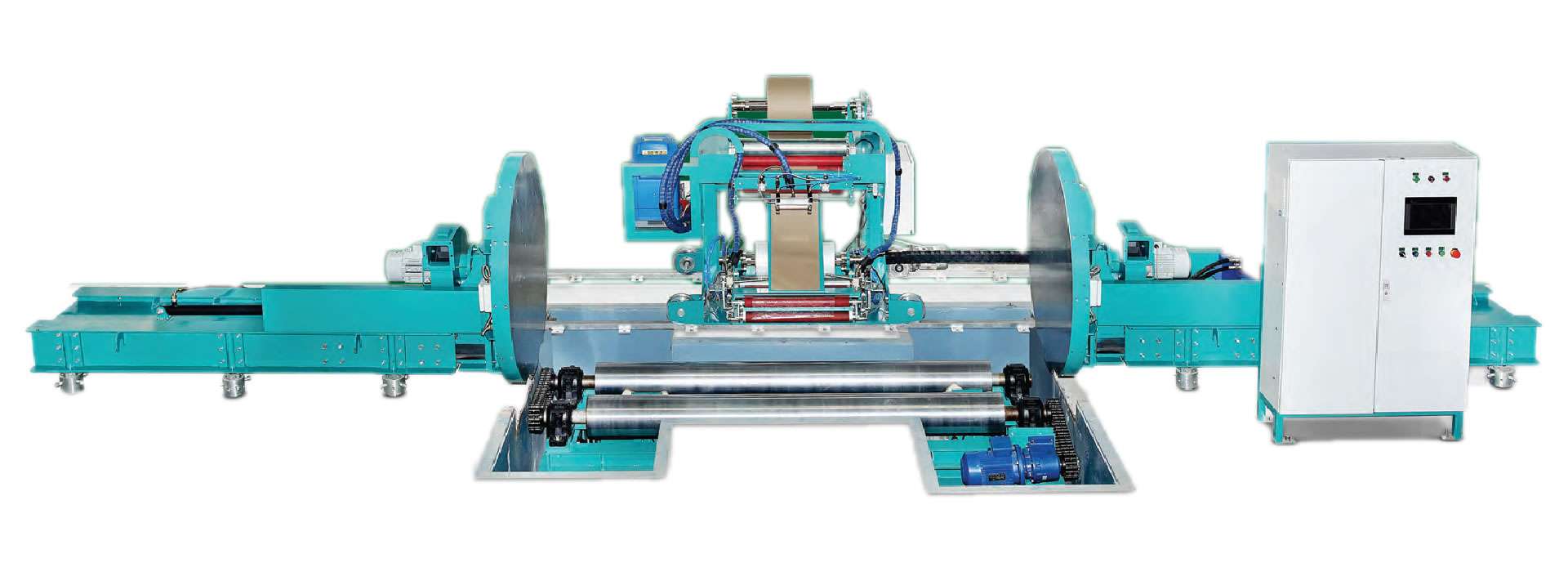

Reel Wrapping Machine

IP-CRW-1600

Inpak Super flexibility of four in one combined film / kraft applicator allows user to select either polyethylrnr or kraft paper as the outer layer of the wrapped package with hot melt gluing and weighing system. Your rolls can "look" like conventionally wrapped rolls if you prefer. Eliminate enviromentally unfriendly laminates from your operation-independently applied film / kraft layer ensure easy-to-separate, fully recyclable package. No need to pay for expensive first quality kraft wrap. Use your own-off-spec wastepaper as wrapping material and add to your mill's profits.

Stretch

Stretch Kraft

Kraft Hot Melt Gluing

Hot Melt Gluing Weighing

Weighing

| Model | : | IP-CRW-1600 |

| Paper roll diameter | : | 700 – 1200mm |

| Paper roll width | : | 400 – 1600mm |

| Roll Max weight | : | 900kgs |

| Over all Power | : | 16 to 20Kw |

| Max. kraft roll diameter | : | 800mm |

| Max. kraft roll width | : | 300mm – 500mm |

| Max. film roll diameter | : | 400mm |

| Max. film roll width | : | 400mm – 500mm |

| Power supply voltage | : | 415 Volt 3Ph – 50 Hz |

| Kraft/Film thickness | : | 80gsm – 140gsm & 17-35 μm |

| Kraft/Film Carriage | : | Powered-stretch film carriage, stretch ratio up to 150% carriage roller opens for effortless roll change & thread film. Film tension adjustable |

| Packing Efficiency | : | 15-20 rolls/hour (7.5MT to 9 MT/hr) |

| Machine Size(L x W x H) | : | 7200mm x 3600mm x 1300mm/2000mm Approx. |

| Total Machine Weight | : | 3600kg apporx |

- Fully automatic operation – Low man power requirements.

- Spiral application : One width wraps all roll sizes, no more need for multiple back stands.

- Separate application of pure Kraft Paper and PE-film = a fully separable, truly recyclable package.

- Kraft wrapping paper of virtually any quality can be used, even off-spec or wastepaper.

- High flexibility : Choose Kraft Paper or PE-film as the outer layer.

- Open design – High accessibility for service and operation.

- Very few moving parts – Minimal downtime for maintenance.

- Film can be used to fold the Kraft down over the inner headers, optional or eliminating the need for outer headers, bottom crimping arms and heated side disc presses.

- Advanced Hot melt gluing system fro high adhesion strength & Rapid drying and curing.

- High acuuracy on line weighing interface system.

- Automatic reel ejection system.

Introducing a new reel wrapping machine with spiral wrapping-based wrapping technology. With substantially lower space needs, minimal shipping costs, and a quick payback period, this technology provides a flexible wrapping idea that is future-focused.

A reel-wrapping machine is a type of packaging equipment that is used to wrap and protect large rolls or reels of materials, such as paper, film, or fabric. The machine typically uses stretch film, shrink film or paper to wrap the reel. The machine also provides tension control to keep the wrapping material tight and secure around the reel, protecting it from damage during transport or storage. These machines are used in many industries such as paper mills, printing companies and others that work with large rolls of materials.

Reel wrapping machines can wrap a large number of reels quickly and efficiently, reducing the time and labour required to manually wrap them. It can provide consistent wrapping quality, ensuring that all reels are wrapped to the same standard. This machine has an advanced hot melt glueing system for high adhesion strength and can very easily dry and cure the glue. Since the machine consists of only a few moving parts and has minimal downtime for maintenance. By automating the wrapping process, reel-wrapping machines can reduce the need for manual labour, resulting in lower labour costs. Reel wrapping machines can help to reduce the risk of injury associated with manual wrapping. It can also help to reduce the amount of waste generated by manual wrapping, thus helping to be more environmentally friendly.

Inpak is the leading manufacturer of other such machines that are needed to fulfil the needs of the industrial sectors. The machines manufactured are highly durable and of uncompromisable quality. Inpak also manufactures shrink bundling machines for wood, food packaging machine, vacuum packing machines, Liquid filling machine, automatic capping machines, Band Sealing Machine, and other packaging machines.

Product Gallery